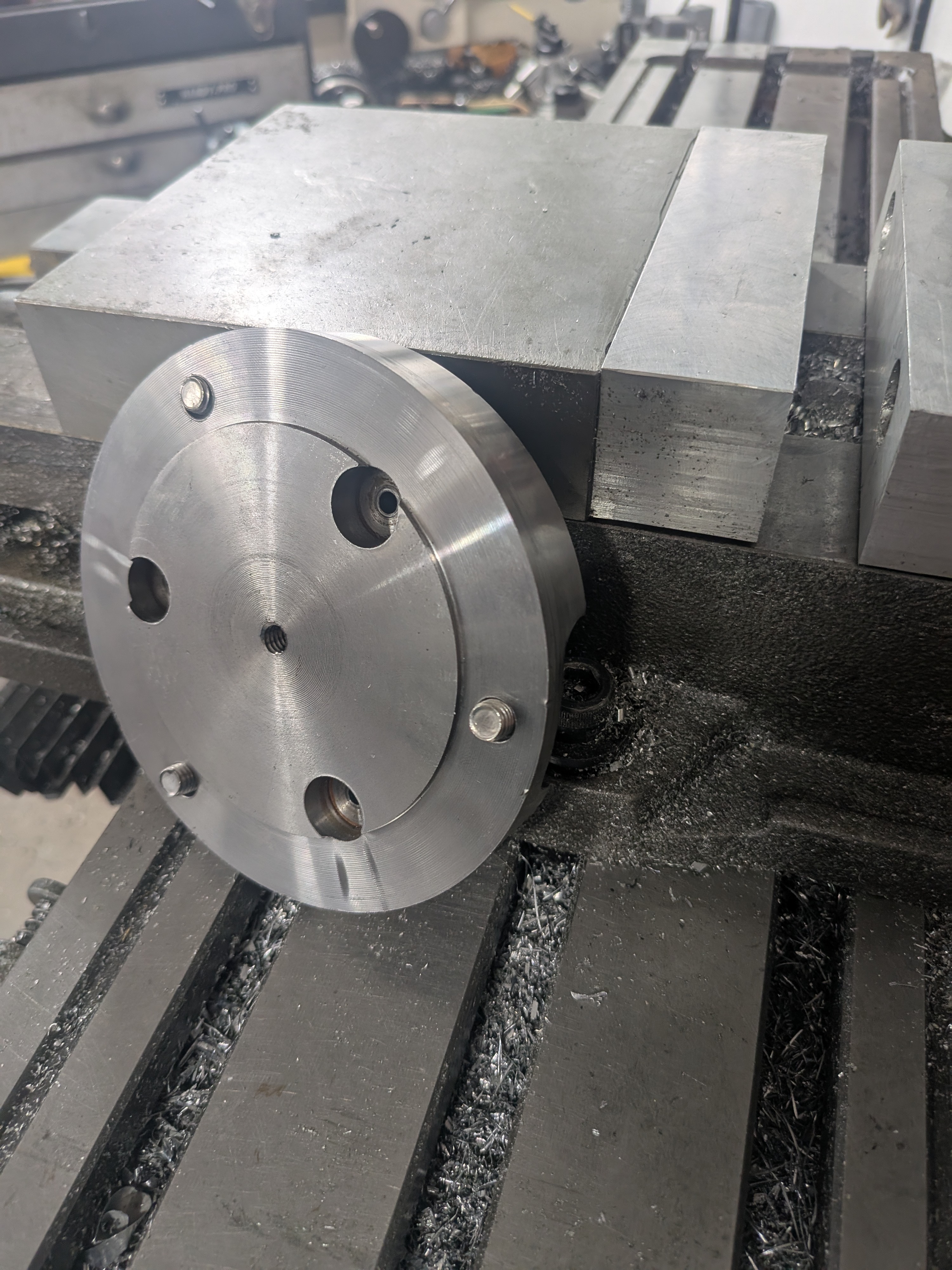

3-Jaw To Rotary Table Adapter

A purpose built adapter between a 4in. 3 jaw chuck and a rotary table. Used for gear making by allowing controlled rotation of stock aligned with the involute cutter on the mill.

Contact: shoestringmachineshop@gmail.com

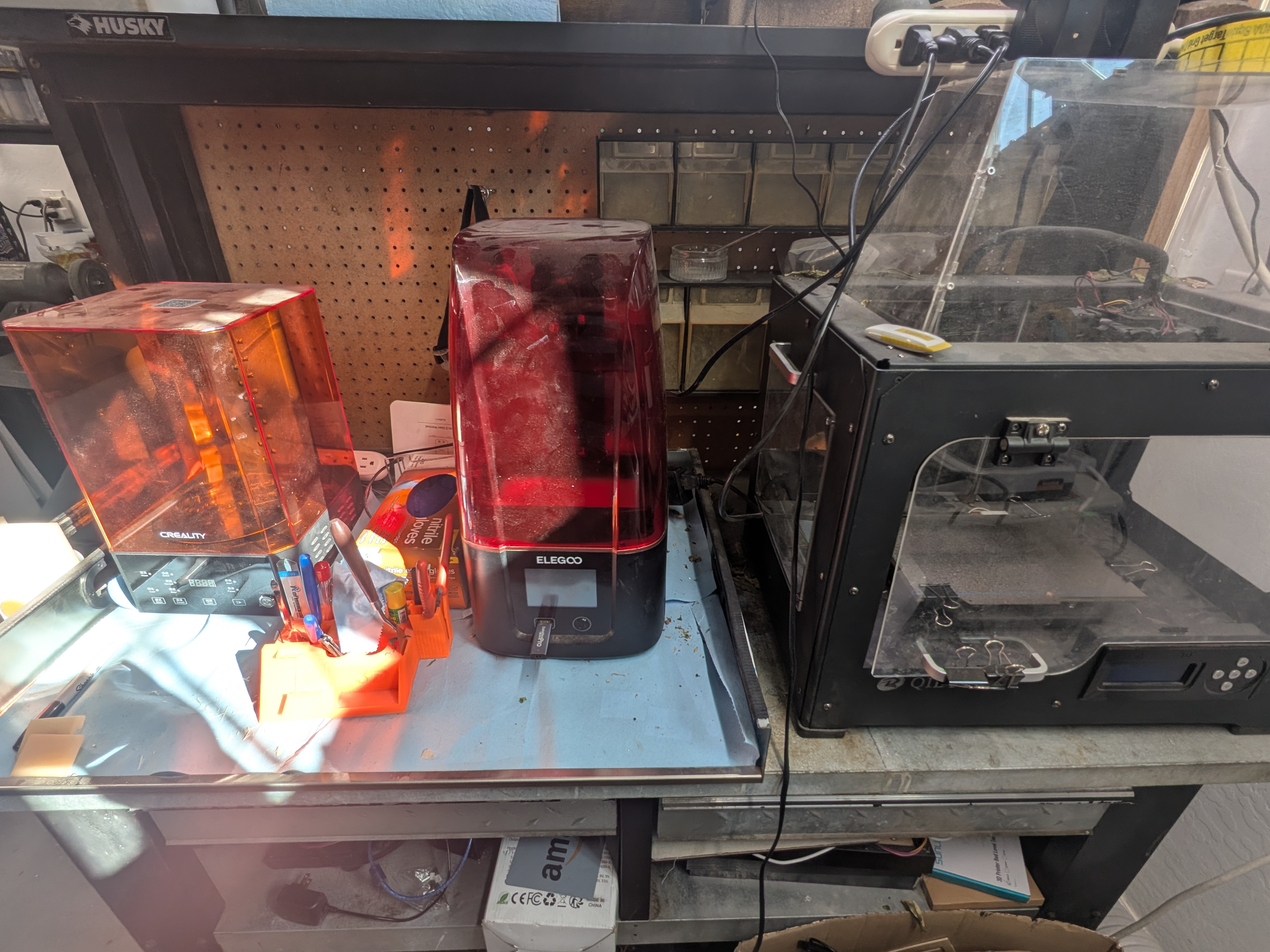

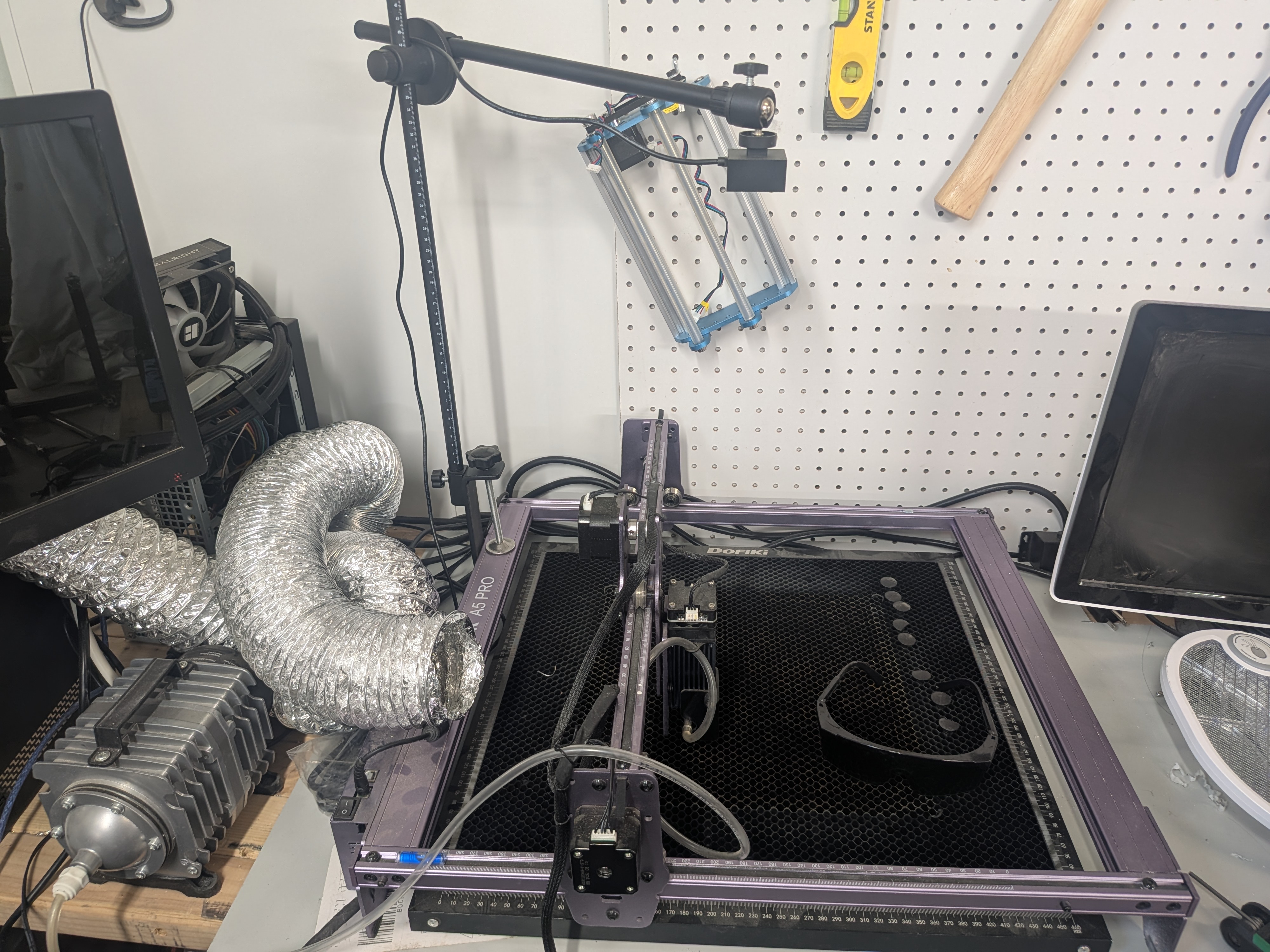

Manual machine shop focusing on small jobs, prototypes, and repairs. Swipe or use the arrows to browse examples for each service.

Need a quote or want to discuss a project? Email us with drawings, photos, or rough dimensions and we'll get back promptly.

A few examples of recent work.

Email us today with a description of your work needed as well as any relevant images or documents and we can scope the project.

Current rates are $45/hour + materials

Contact: shoestringmachineshop@gmail.com

Notes:

Shoestring Machine Shop is a small garage scale business. Tight tolerances may be difficult to hit (but we'll try!). Complex geometries like curves or helixes are better serviced by full cnc machine shops. We focus on those smaller scale one off jobs that just don't make sense for the larger shops to spend the cnc tool time and setup on. Sometimes you just need a slot cut or a bushing made and are on a tight... perhaps shoestring... budget. That is what this shop is for!